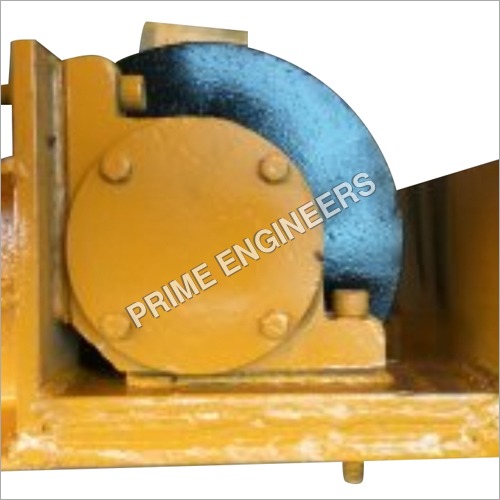

End Carriage

Price 250000.00 INR/ Set

MOQ : 1 Set

End Carriage Specification

- Color

- Yellow / Custom

- Brake

- Electromagnetic Brake

- Emergency Stop

- Available

- Electric Hoist

- Compatible

- Application

- Overhead Crane, Gantry Crane, EOT Crane

- Gearbox

- Helical/Bevel Gear Reducer

- Traveling Speed

- 20 m/min

- Condition

- New

- Load Capacity

- 1-20 Ton

- Max. Lifting Height

- Up to 30 meter

- Max. Lifting Load

- 20 Ton

- Rated Lifting Moment

- Standard

- Span

- 1-30 meter

- Lifting Mechanism

- End Carriage Mounted

- Lifting Speed

- 5 m/min

- Operating Mode

- Pendant, Wireless Remote, Cabin Control

- Power Supply

- 3 Phase AC

- Voltage

- 380V/415V/440V

- Ambient Temperature

- -20C to +55C

- Coating

- Anti-corrosive Paint

- Working Duty

- M5/M6 (Medium/Heavy Duty)

- Drive Type

- Double Driven Twin End

- Noise Level

- 80 dB

- Material

- High Strength Steel

- Mounting Type

- Direct Bolt-On

- Protection Class

- IP54 / IP55

- Wheel Type

- Forged Steel Wheels

End Carriage Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Day

- Delivery Time

- 1 Days

About End Carriage

We are able to supply a fine grade of L Block End Carriage, which is fabricated from steel rolled plate depending on the required capacity. This carriage is convenient to handle and mostly applicable for small production warehouses. It is known for its safety specifications and simple reception. L Block Type End Carriage is formed in a L style shape and compact construction to face all the hard challenges in a smoother manner.

Robust Build and Protection

Engineered with premium high strength steel and coated with anti-corrosive paint, the end carriage resists wear and corrosion, making it well-suited for heavy-duty industrial settings. The IP54/IP55 protection class ensures that internal components remain safe from dust and water, even in harsh working environments across India.

Precision and Efficiency

The forged steel wheels and double driven twin end system are designed for smooth, accurate travel, minimizing vibration and operational noise ( 80 dB). With a traveling speed of 20 m/min and a standard lifting speed of 5 m/min, efficiency and productivity are optimized for various crane applications including overhead, gantry, and EOT cranes.

Flexible Operation and Safety

This end carriage provides versatile control options such as pendant, wireless remote, and cabin operation. The integrated electromagnetic brake and the emergency stop feature enhance safety during lifting. Its direct bolt-on mounting simplifies installation and enables quick commissioning for manufacturers, suppliers, and service providers.

FAQs of End Carriage:

Q: How is the end carriage installed for cranes?

A: The end carriage features a direct bolt-on design, enabling quick and straightforward installation. Align the carriage with the crane structure, secure it using the provided bolts, and connect the electric and control systems as per the instructions. Professional installation ensures optimal safety and performance.Q: What applications are best suited for this end carriage?

A: This end carriage is ideal for overhead cranes, gantry cranes, and EOT cranes used in warehouses, workshop facilities, manufacturing plants, and logistics hubs. Its robust design supports medium and heavy-duty material handling tasks across multiple industries.Q: When is maintenance required for optimal performance?

A: Routine maintenance such as lubrication of moving parts, inspection of brake and gearbox systems, and checking for wear or corrosion is recommended every 3-6 months, depending on usage intensity. Keeping to a maintenance schedule ensures longevity and reduces downtime.Q: Where can this end carriage be supplied or serviced in India?

A: The end carriage is available through dealers, distributors, fabricators, manufacturers, producers, retailers, service providers, suppliers, traders, and wholesalers across India. Many of these entities also provide after-sales service and technical support.Q: What benefits does the double driven twin end drive offer?

A: The double driven twin end drive ensures balanced power distribution to both sides of the carriage, resulting in smooth, stable movement. This configuration minimizes wear on components and enhances the overall reliability and lifespan of the crane system.Q: How does the anti-corrosive paint and IP class protect the carriage?

A: The anti-corrosive paint shields the high strength steel from rust and humidity, while the IP54/IP55 rating guards internal elements against dust and water ingress. Together, these features ensure reliable operation in diverse and challenging environments.Q: What safety features are integrated into the end carriage?

A: The end carriage comes equipped with an electromagnetic brake for precise stopping, an emergency stop mechanism for instant shutdown, and a robust gearbox system. These features prioritize safe lifting and movement, protecting operators and equipment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in End Carriage For EOT Crane Category

High Capacity End Carriage

Price 125000.00 INR / Set

Minimum Order Quantity : 1 Number

Color : Yellow / Customized

Power Supply : 3 Phase AC

Condition : New

EOT Crane End Carriage

Price 65000 INR / Set

Minimum Order Quantity : 1 Number

Color : Yellow

Power Supply : Electric

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese