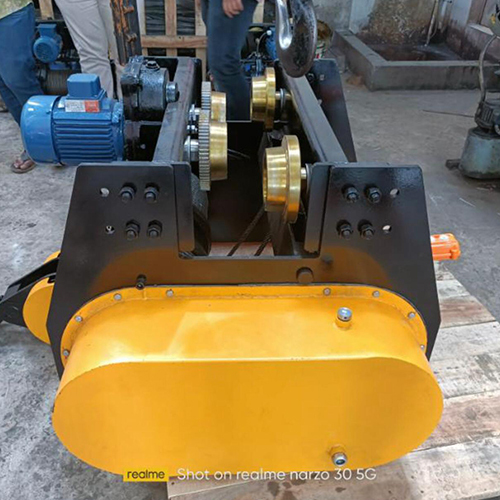

Overhead Eot Crane

Price 45000.00 INR/ Set

MOQ : 1 Number

Overhead Eot Crane Specification

- Emergency Stop

- Provided

- Electric Hoist

- Included

- Brake

- Heavy Duty Electromagnetic

- Application

- Material Handling in Workshops, Warehouses, Factories

- Traveling Speed

- 20-60 m/min

- Gearbox

- Helical or Planetary Type

- Color

- Yellow or Customized

- Condition

- New

- Load Capacity

- 5-50 Ton

- Max. Lifting Height

- 6-30 m

- Max. Lifting Load

- 50 Ton

- Rated Lifting Moment

- As per design

- Span

- 10-30 m

- Lifting Mechanism

- Wire Rope Hoist

- Lifting Speed

- 5-10 m/min

- Operating Mode

- Pendant Control / Remote Control / Cabin Control

- Power Supply

- 3 Phase AC

- Voltage

- 380V/415V/440V

- Painting

- Two Coats Primer & Synthetic Enamel

- Insulation Class

- Class F/H

- Crane Type

- Single Girder / Double Girder

- Material

- Mild Steel, IS 2062 Grade

- Control Panel

- Enclosed, Dust & Weatherproof

- Protection Class

- IP54/IP55

- Limit Switches

- Yes, for Hoisting & Cross Travel

- Hoisting Motor

- Squirrel Cage or Slip Ring

- Duty Class

- ISO/FEM Standard Medium to Heavy Duty

- Wheels

- Forged Steel/EN8 Material

- Working Temperature

- -20°C to +60°C

Overhead Eot Crane Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 2 Per Day

- Delivery Time

- 1 Days

About Overhead Eot Crane

Overhead Eot Crane is a type of crane widely used for heavy lifting in industrial environments. These are commonly used in industries like steel, automotive, construction, and manufacturing for lifting and transporting large, heavy objects over long distances. It is an electrically powered crane that moves along a horizontal track (runway) and is capable of lifting and transporting heavy loads across a facility or workspace. With its high lifting capacity, efficient operation, and customizable features, it is an invaluable tool in industries like steel manufacturing, construction, automotive, and warehouses. Overhead Eot Crane can cover large areas, moving materials between different points of the facility, making them adaptable for different types of operations.

Engineered for Industrial Excellence

Constructed with IS 2062 grade mild steel, this EOT crane fulfills ISO/FEM standards for medium to heavy-duty operations. Its innovative design ensures longevity and resilience, while forged steel wheels and wire rope hoists enable smooth, efficient workflows.

Versatile Applications and Customization

These cranes serve a wide spectrum of industries, including manufacturing, logistics, and warehousing. Options for single or double girder variants, span up to 30 meters, and finish customization (standard yellow or bespoke colors) ensure a perfect fit for your operational requirements.

Safety and Advanced Control Features

Equipped with emergency stops, enclosed control panels, limit switches for hoisting/cross travel, and robust insulation, safety is paramount. Operators can choose from pendant, remote, or cabin controls, optimizing convenience and minimizing downtime during operations.

FAQs of Overhead Eot Crane:

Q: How does the Overhead EOT Crane support different lifting requirements across industries?

A: The crane accommodates a wide range of lifting capacities (5 to 50 tons) and maximum heights (up to 30 meters), making it suitable for various applications like workshops, warehouses, and factories, depending on the load and operational needs.Q: What are the control options available for operating this EOT crane?

A: Operators can manage the crane using pendant control, wireless remote control, or from an operator cabin, providing flexibility and safety for different working environments and user preferences.Q: When should I choose a single girder versus a double girder design?

A: A single girder configuration is optimal for lighter to moderate loads and limited space, while a double girder design is ideal for heavier lifting tasks, extended spans, or applications demanding maximum lifting heights.Q: Where is the Overhead EOT Crane best utilized?

A: This crane is ideal for material handling in indoor industrial environments such as workshops, warehouses, and manufacturing plants, offering robust performance and adaptability to various operational layouts.Q: What safety features are built into the cranes design?

A: Safety is prioritized through emergency stop mechanisms, limit switches on hoisting and cross travel, enclosed dust- and weatherproof control panels, and IP54/IP55 protection for electrical components, ensuring secure and uninterrupted performance.Q: How does the painting and protection process benefit the cranes longevity?

A: A dual-coat primer followed by synthetic enamel paint guards the crane against corrosion and wear, complemented by IP-rated protection (IP54/IP55), making it resilient in challenging industrial environments for a longer lifespan.Q: What advantages does using a heavy-duty electromagnetic brake offer?

A: The inclusion of a heavy-duty electromagnetic brake ensures precise, reliable stopping and holding of loads, enhancing safety and providing secure load control during hoisting and lowering operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in EOT Cranes Category

WIRE ROPE HOISTS

Price 75000.00 INR / Set

Minimum Order Quantity : 1 Set

Color : Blue/Yellow/Custom

Condition : New

Power Supply : Three Phase AC

Hand Operated Overhead Cranes

Price 30000.00 INR / Set

Minimum Order Quantity : 1 Number

Color : Yellow / Customized

Condition : New

Power Supply : Not Required (Manual Operation)

Electric Wire RopeHoist -1Ton

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Condition : New

Power Supply : Electric

Product Type : Electric Wire RopeHoist 1Ton

5Ton Electric Hoist

Price 95000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Condition : New

Power Supply : Electric

Product Type : 5Ton Electric Hoist

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese